Challenges for EV Manufacturers | Electric vehicles are transforming the automotive industry, offering numerous environmental and economic advantages. EVs produce zero tailpipe emissions, reducing greenhouse gas emissions and improving air quality. Moreover, the declining costs of battery technology and supportive government policies have accelerated the adoption of EVs. According to recent statistics, global EV sales reached a record 3.24 million units in 2020, representing a 43% increase compared to last year.

Despite this growth, EVs account for only about 4% of total global vehicle sales, highlighting the challenges that lie ahead for manufacturers. Let’s read further on the challenges faced by EV manufacturers.

EV Manufacturer Challenges & Solutions

The major challenges facing EV manufacturers are as follows:

- Battery Technology and Range Anxiety

- Charging Infrastructure

- Supply Chain and Raw Materials

- Cost Competitiveness

- Consumer Education and Awareness

EV Manufacturer Challenge #1 – Battery Technology and Range Anxiety

The first major challenge for EV manufacturers revolves around battery technology and the issue of range anxiety. EVs rely on lithium-ion batteries for energy storage, and while battery costs have decreased significantly, there is still room for improvement. Manufacturers are striving to enhance battery performance, increase energy density, and reduce charging times to address consumer concerns.

Extending the driving range is one of the key challenges EV technology faces. It is crucial for wider adoption, as customers remain hesitant due to the fear of running out of charge. To tackle this challenge, manufacturers are investing in research and development to develop advanced battery chemistries, solid-state batteries, and fast-charging infrastructure, all aimed at providing longer ranges and minimizing charging time.

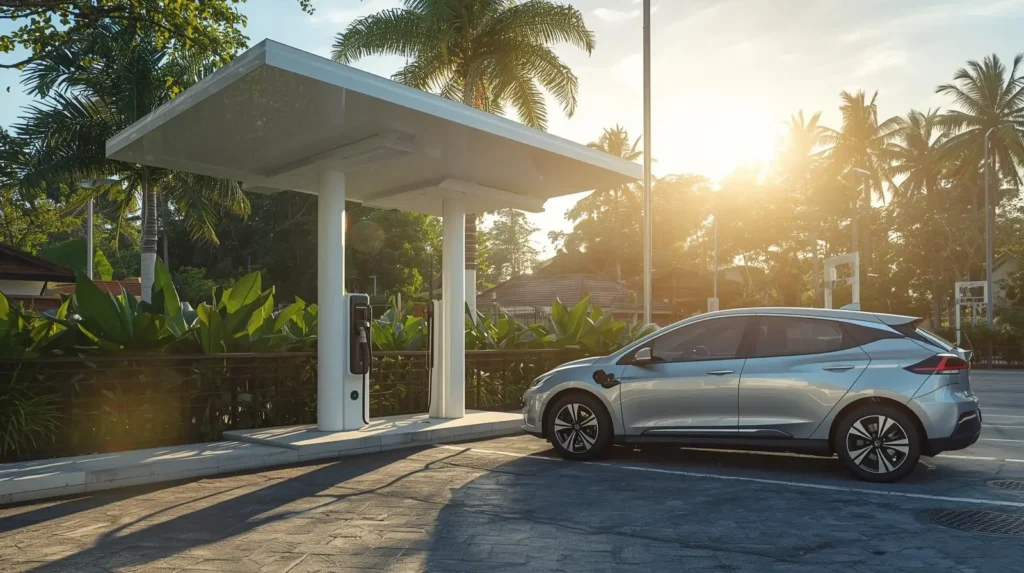

EV Manufacturer Challenge #2 – Charging Infrastructure

The availability and accessibility of charging infrastructure pose another significant challenge for EV manufacturers. To alleviate range anxiety and provide convenience to EV owners, a robust and widespread charging network is essential. However, establishing an extensive charging infrastructure requires significant investment and collaboration between manufacturers, governments, and energy providers.

Manufacturers are actively engaging in partnerships and collaborations to expand public charging networks, installing high-speed chargers along major highways and in urban areas. Moreover, the development of smart charging systems and vehicle-to-grid (V2G) technology will optimize charging infrastructure utilization. This optimization will ensure efficient power distribution and enable bi-directional energy flow between electric vehicles (EVs) and the grid.

EV Manufacturer Challenge #3 – Supply Chain and Raw Materials

As EV production scales up, manufacturers face challenges in securing a reliable supply chain for key components and raw materials. The production of EVs requires a significant amount of lithium, cobalt, nickel, and other rare-earth metals, leading to concerns over their availability and sustainable sourcing.

Manufacturers are proactively pursuing alternative materials, such as solid-state batteries (ref)that use less cobalt or even cobalt-free chemistries, to reduce reliance on scarce resources. Additionally, efforts are being made to establish transparent and responsible supply chains. This includes ensuring the ethical sourcing of raw materials and reducing the environmental impact of EV production.

EV Manufacturer Challenge #4 – Cost Competitiveness

Cost remains a significant barrier to mass EV adoption. While the price of EVs has decreased in recent years, they are still relatively more expensive than traditional internal combustion engine vehicles. EV manufacturers are focused on achieving cost competitiveness through economies of scale, technological advancements, and battery cost reductions.

Streamlining manufacturing processes, optimizing battery production, and investing in research and development are key strategies employed to drive down costs. Furthermore, government incentives and subsidies play a crucial role in making EVs more affordable and incentivizing consumer adoption. Lobbying the government to allow for better policies is another one of the many key challenges for EV adoption.

EV Manufacturer Challenge #5 – Consumer Education and Awareness

Educating consumers and raising awareness about electric vehicles is a mix of challenges and opportunities. They need to know about the benefits and practicality of EVs for widespread adoption. Many potential EV buyers still need to learn about range limitations, charging infrastructure, and overall performance compared to conventional vehicles.

EV manufacturers are making efforts by involving in marketing campaigns and educational initiatives. They are also collaborating with government and environmental organizations to disseminate accurate information and dispel myths associated with EVs. Moreover, manufacturers are working to enhance customer experiences by offering test drives and personalized consultations. They also provide comprehensive after-sales support to address customer concerns.

Online platforms take this one step further, allowing customers to search and compare EV models and even make remote purchases. EV Charging Subscription models are also now available for customers who prefer flexible ownership options.

Conclusion

We hope you have gained insight into the EV market value, challenges faced by EV manufacturers and their solutions to tackle them. For more insights on the EV charging industry, you can visit our website. YoCharge is a turnkey EV Charging Software Provider that is well known for White Label EV Charging Software platforms that help EV businesses brand and launch their EV charging business platforms in just seven days.