The Main Components of Electric Vehicles

Electric vehicles consists of an electric motor that is powered by a battery pack. The main advantage of electric vehicle components is that they emit zero emissions and are eco-friendly. They also do not consume any fossil fuels, hence use a sustainable form of energy for powering the car. The main components of electric vehicles are :

- Traction battery pack

- DC-DC Converter

- Electric motor

- Power inverter

- Charge Port

- Onboard charger

- Controller

- Auxiliary batteries

- Thermal system (cooling)

- Transmission

1. Traction Battery Pack

Traction battery pack is also known as Electric vehicle battery (EVB). It powers the electric motors of an electric vehicle. The battery acts as an electrical storage system. It stores energy in the form DC current. The range will be higher with increasing kW of the battery. The life and operation of the battery depends on its design. The lifetime of a traction battery pack is estimated to be 200,000 miles.

2. DC-DC Converter

The traction battery pack delivers a constant voltage. But different components of electric vehicle has different requirements. The DC-DC convertor distributes the output power that is coming from the battery to a required level. It also provides the voltage required to charge the auxiliary battery.

3. Electric motor

Electric traction motor is the main components of electric vehicles. The motor converts the electrical energy into kinetic energy. This energy rotates the wheels. Electric motor is the main components of electric vehicle that differentiates an electric car from conventional cars. An important feature of an electric motor is the regenerative braking mechanism. This mechanism slows down the vehicle by converting its kinetic energy into another form, and storing it for future use. There are basically two types of motors DC and AC motors.

Related article

Detailed working of an electric motor

4. Power Inverter

It coverts DC power from the batteries to AC power. It also converts the AC current generated during regenerative braking into DC current. This is further used to recharge the batteries. The inverter can change the speed of the

5. Charge Port

The charge port connects the electric vehicle to an external supply. It charges the battery pack. The charge port is sometimes located in the front or rear part of electric vehicle components.

6. Onboard charger

Onboard charger is used to convert the AC supply received from the charge port to DC supply. The on-board charger is located and installed inside the car. It monitors various battery characteristics and controls the current flowing inside the battery pack.

7. Controller

Power electronics controller determines the working of an electric car. It performs the regulation of electrical energy from the batteries to the electric motors. The pedal set by the driver determines the speed of the car and frequency of variation of voltage that is input to the motor. It also controls the torque produced.

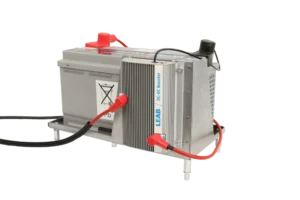

8. Auxiliary batteries

Auxiliary batteries are the source of electrical energy for the accessories in electric vehicles. In the absence of the main battery, the auxiliary batteries will continue to charge the car. It prevents the voltage drop, produced during engine start from affecting the electrical system.

9. Thermal system(cooling)

The thermal management system is responsible for maintaining an operating temperature for the main components of electric vehicle (EV) such as, electric motor, controller etc. It functions during charging as well to obtain maximum performance. It uses a combination of thermoelectric cooling, forced air cooling, and liquid cooling.

10. Transmission

The gearbox transfers the mechanical power from the electric motor to the wheels. The advantage of electric cars is that they do not require multi-speed transmissions. The transmission efficiency should be high to avoid power loss.

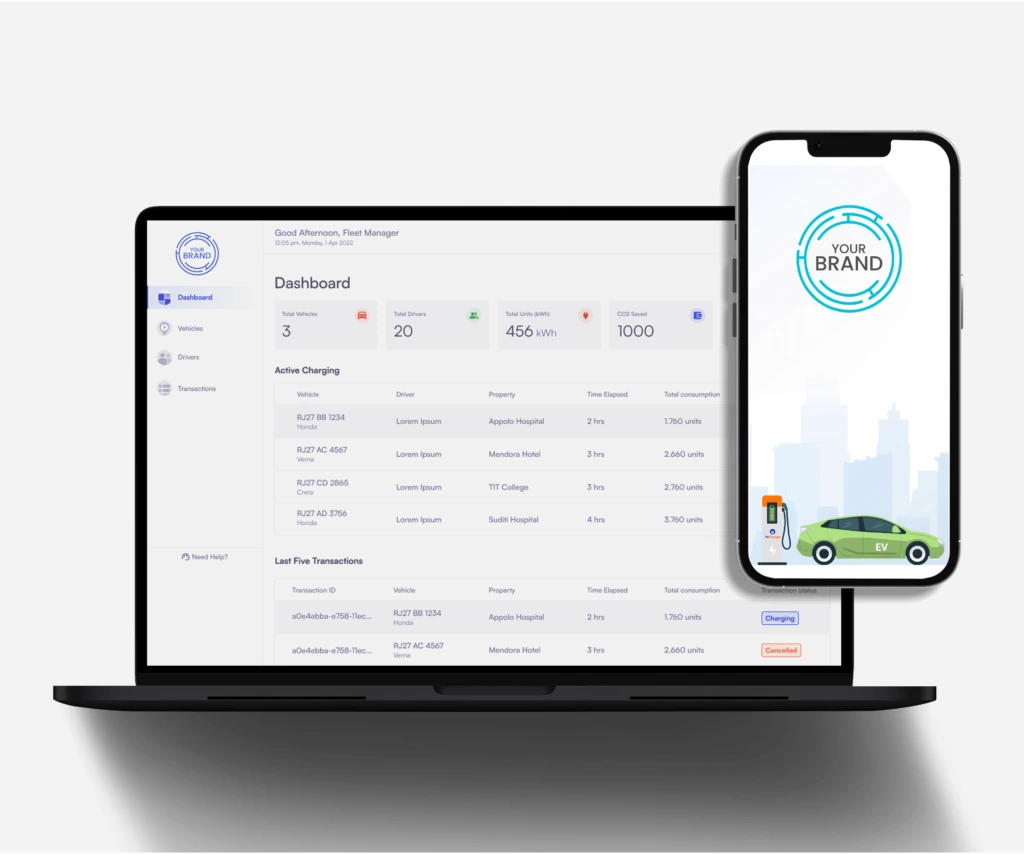

EV CHARGING APPS

Launch Your OWN EV Charging Business

Launch your own EV Charging Station Network brand in 7 days without any technology development & manpower deployment. Completely automated solution with admin dashboards & branded Android & IoS mobile applications.

You can also watch a video