Electric batteries are the source of energy of electric vehicles. There are different types of electric batteries depending on the type of electric vehicle. Let us discuss about the different types of batteries in electric vehicles in detail :

The different types of electric vehicle batteries:

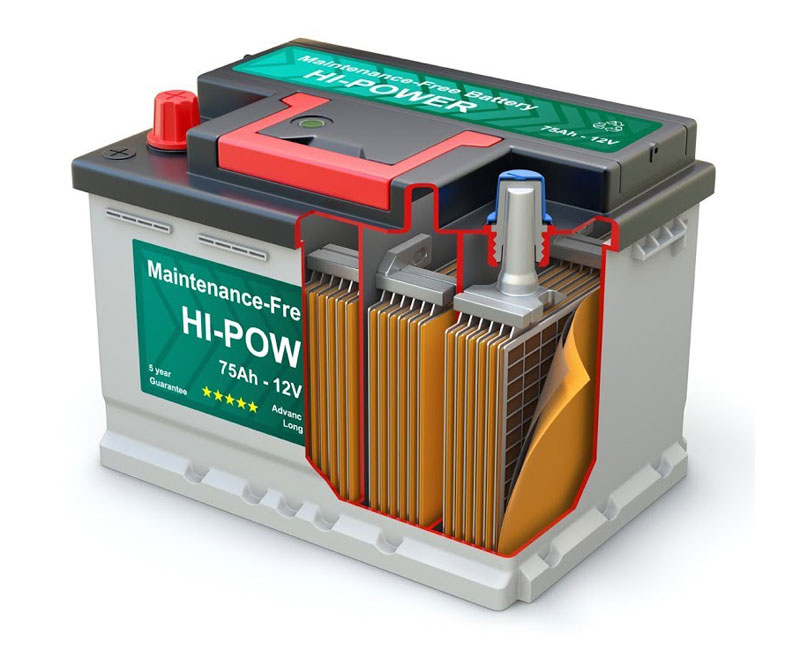

1. Lead-Acid Batteries

Lead-Acid Batteries are the very first rechargeable battery ever made. Lead–acid batteries have a low energy density when compared to current rechargeable batteries. Despite this, the cells have a high power-to-weight ratio due to their capacity to supply strong surge currents. These characteristics, combined with their low cost, make them appealing for use in automobiles to supply the high current needed by starter motors.

Lead acid batteries are relatively heavy—and dangerous since they contain toxic lead and harmful sulfuric acid. While being charged, lead acid batteries can release hydrogen gas, which can cause a fire or explosion if not properly ventilated. They are only used in commercial electric drive vehicles with incidental powers.

2. Lithium-Ion batteries

A lithium-ion battery, often known as a Li-ion battery, is a rechargeable battery made up of cells in which lithium ions travel from the negative electrode to the positive electrode through an electrolyte during discharge and then back again during charging. The positive electrode of a lithium-ion cell is made of an intercalated lithium compound, while the negative electrode is usually made of graphite.

They are widely used in consumer electronics and transportation, because they have high energy per unit mass as compared to other type of batteries. They also have a high power-to-weight ratio, excellent high-temperature performance, and low self-discharge. In addition they offer a better lifespan. Also with the help of an electronic circuit they have a good control on the recharging process.

Most of the components of Lithium-ion batteries are recyclable but the cost of recovery is high. They are widely used in PHEVs and electric vehicles.

Lithium Nickel manganese Cobalt Oxide batteries often known as NMC batteries. They are made up of a range of materials used in lithium-ion batteries. A nickel, manganese, and cobalt-based cathode is used. Like other lithium-ion battery types, NMC batteries can have a high specific energy density or specific power. The most popular applications for this battery are power tools and car powertrains.

3.Nickel-Metal Hydride Batteries

Nickel- Metal Hydride batteries are widely used in HEVs. The chemical reaction happening at the positive electrode is comparable to that of the nickel–cadmium cell (NiCd), as both use nickel oxide hydroxide (NiOOH). The negative electrodes, on the other hand, are made of a hydrogen-absorbing alloy rather than cadmium. NiMH batteries can have two to three times the capacity of NiCd batteries of the same size, as well as a substantially better energy density than lithium-ion batteries, but at a lower cost.

Nickel-metal hydride (Ni-MH) accumulators have had more success than Ni-Cd accumulators since they do not contain heavy metals. At the beginning of the century, this portable rechargeable battery technology was the most cost-effective. Nickel-metal hydride batteries face several issues, including high cost, high self-discharge and heat generation at high temperatures, and the reduction of hydrogen loss.

4.Ultra-capacitors

Between an electrode and an electrolyte, ultracapacitors(supercapacitors) store energy in a polarised liquid. As the surface area of a liquid grows, so does its energy storage capacity. Ultracapacitors can help vehicles recover braking energy and give more power during acceleration and hill climbing. Because they help electrochemical batteries level load power, they could be helpful as auxiliary energy storage devices in electric cars.

They excel in meeting a wide range of energy needs in a short amount of time. Ultracapacitors can withstand up to 1 million charging cycles due to the lack of chemical interactions. However, they cannot hold the same amount of charge as a Li-ion battery. The main advantage it provides is rapid charging and discharging.

| Parameter | Lead-Acid | Lithium Ion | Nickel-Metal | Ultra-Capacitor |

|---|---|---|---|---|

| Energy Efficient | Yes | Yes | Yes | Yes |

| Temperature Performance | Yes | No | No | Yes |

| Weight | Yes | Yes | Yes | Yes |

| Inexpensive | Yes | Yes | No | No |

| Life-cycle |